Description

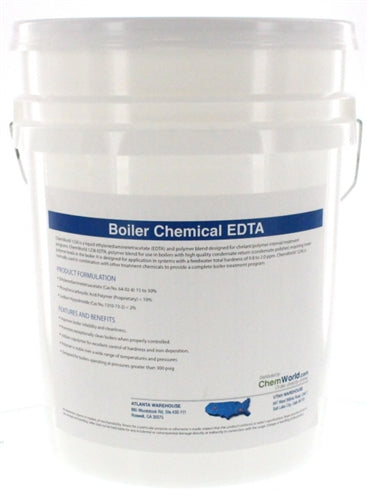

Boiler Chemical EDTA

ChemWorld 1236 is a liquid ethylenediaminetetracetate (EDTA) and polymer blend designed for chelant/polymer internal treatment programs. ChemWorld 1236 EDTA, polymer blend for use in boilers with high quality condensate return (condensate polisher) requiring lower polymer levels in the boiler. It is designed for application in systems with a feedwater total hardness of 0.8 to 2.0 ppm. ChemWorld 1236 is normally used in combination with other treatment chemicals to provide a complete boiler treatment program.

PRODUCT FORMULATION

- Ethylenediaminetetraacetate (Cas No. 64-02-8) 15 to 30%

- Phosphinocarboyxlic Acid Polymer (Proprietary) < 10%

- Sodium Hypodroxide (Cas No. 1310-73-2) < 2%

FEATURES AND BENEFITS

- Improves boiler reliability and cleanliness.

- Promotes exceptionally clean boilers when properly controlled.

- Utilizes copolymer for excellent control of hardness and iron deposition.

- Polymer is stable over a wide range of temperatures and pressures.

- Designed for boilers operating at pressures greater than 300 psi

ChemWorld 1236 is normally fed continuously to the system being treated. The product may either be fed neat directly from the shipping container or mixed in a chemical feed tank using good quality condensate, softened water, or feedwater. Tanks, pumps, piping and valves should be made of stainless steel, polyethylene, or PVC. For injection into the system, a stainless steel injection nozzle in the feedwater line downstream of the feedwater pumps, economizer, or any bronze or copper alloys is required to assure optimum safety. Do not grossly overfeed.

Control of ChemWorld 1236 is by microhardness test. (A chelant residual test should not be used to control feed rate.) Overfeed of this product may cause damage to the boiler system. The technical specialist servicing the facility will provide specific treatment control levels based on system conditions.

EDTA, polymer blend for use in boilers with high quality condensate return (condensate polisher) requiring lower polymer levels in the boiler. Feedwater total hardness of 0.8 to 2.0 ppm.

This product is typically used with a 3 or 4 drum water treatment program. When using an EDTA chemical we always recommend using a softener system with a boiler conductivity controller. Also, use a hardness test kit to verify the softener performance by testing the boiler water and feed water hardness.

For new steam boiler startups, consider purchasing our Steam Boiler Startup Kit.